- #HOW TO OPEN A FEATURE CAM DOCUMENT WITHOUT FEATURE CAM HOW TO#

- #HOW TO OPEN A FEATURE CAM DOCUMENT WITHOUT FEATURE CAM SOFTWARE#

Coordinate values for the required axis positions and motions are automatically derived from geometry inherent in the 3D part model, as most of today's CAM packages do. The next command is to generate tool paths, based on the set of operations already established. Connecting features to proven machining operations is the genius of knowledge-based machining. The user can let default values be applied, or the database can be customized to reflect shop preferences. The database includes machining parameters such as speeds and feeds that match the operation, the selected tool, and the workpiece material. These features then can be linked to machining routines and corresponding cutting tools stored in a database. Interactively recognized features are also inserted in the tree. So once CAMWorks has recognized the features, they are listed by workplane in a feature tree following the order in which they were recognized. The set of prismatic features supported by a library of machining operations grows with each release of the software. These generally fall into categories of holes with vertical walls, pockets and bosses.

#HOW TO OPEN A FEATURE CAM DOCUMENT WITHOUT FEATURE CAM SOFTWARE#

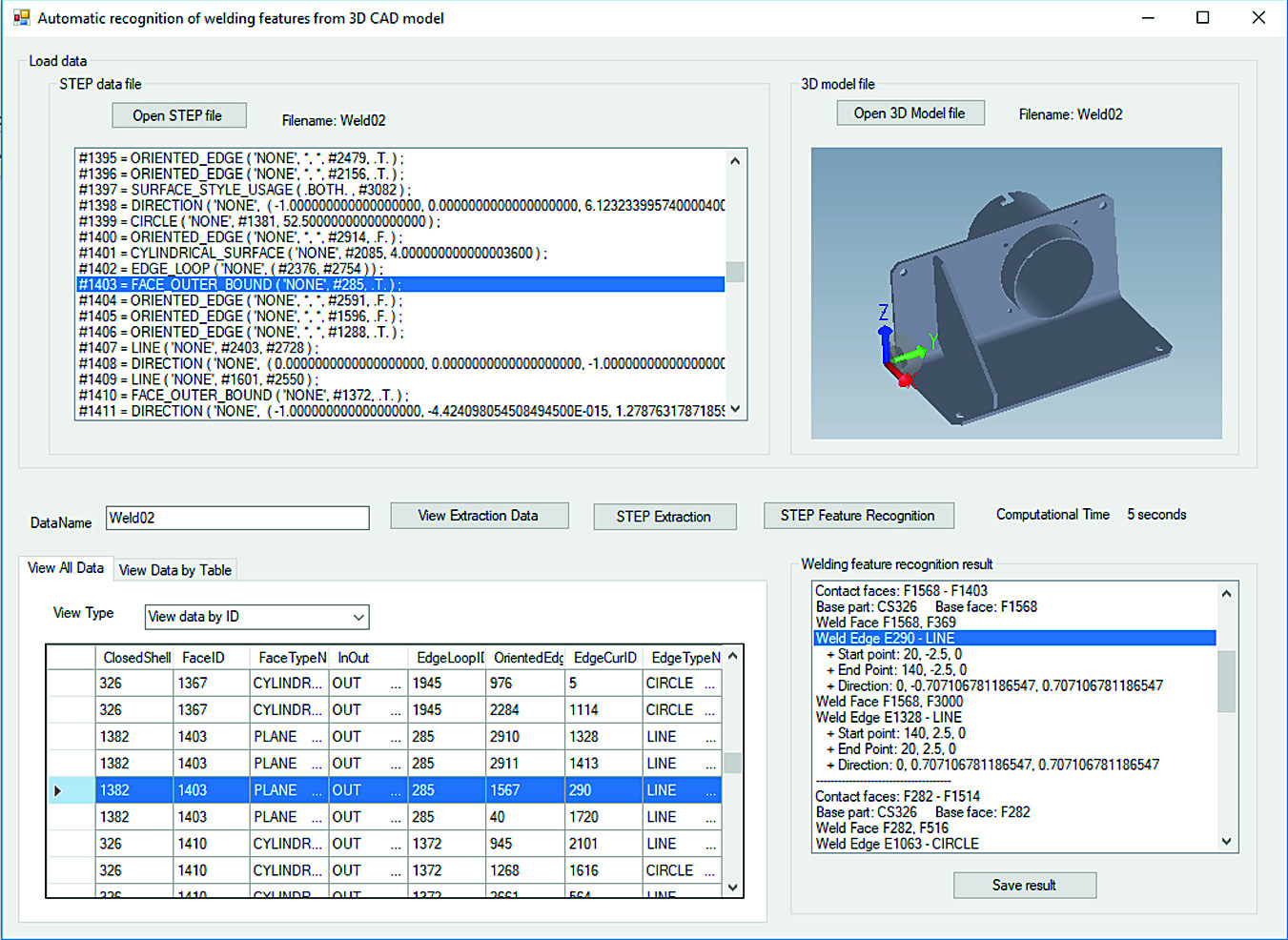

Currently, the software recognizes most prismatic features that lend themselves to 2½-axis machining. The software automatically analyzes the part model and identifies machinable features based on the part's geometry (the shape of the feature) and topology (how the features are related to each other). The user clicks on the Extract Machining Command. Here is a somewhat simplified description of the steps to creating a CNC program to produce a workpiece represented by the solid model. (Turning is also available.) This application starts with a 3D solid model created in SolidWorks or imported via IGES or other exchange formats. This is easiest to see in the CAMWorks milling application. In the world of CNC machining, this essential job of interpreting design data usually falls to the CNC programmer.ĬAMWorks is being billed as "the closest thing to point and click machining available." How close is up to the CAM market to decide, but the concept of point and click machining highlights the potential of feature recognition. Part features as represented in design geometry must be identified correctly and linked with the appropriate machining strategy because nobody wants to end up making white elephants on the shop floor.

#HOW TO OPEN A FEATURE CAM DOCUMENT WITHOUT FEATURE CAM HOW TO#

In manufacturing, of course, there is no room for anything but being entirely right about how to machine a workpiece in order to fulfill the designer's intent. Each of the blind men is partly right and each is partly wrong, the poem concludes. Another proclaims that the elephant's floppy ear is very like a fan, and so on. The one who catches the trunk says that an elephant must be very like a snake. The one who grasps the tail insists that an elephant must be very like a rope. The one who feels the tusk declares that an elephant must be very like a spear. Each one touches a different part of the animal's body.

Previous NextĪ famous poem based on a fable from India describes six blind men who encounter an elephant for the first time. A STEP NC super model was downloaded from the Internet to the control unit on this milling machine to show how a file of product data can contain all of the information required by a CNC to machine the part.

0 kommentar(er)

0 kommentar(er)